Pressure Die Casting

Start Prototyping is a China-based die casting manufacturer, who offers machining and casting solutions at affordable prices!

Pressure Die Castings Service

OVERVIEW

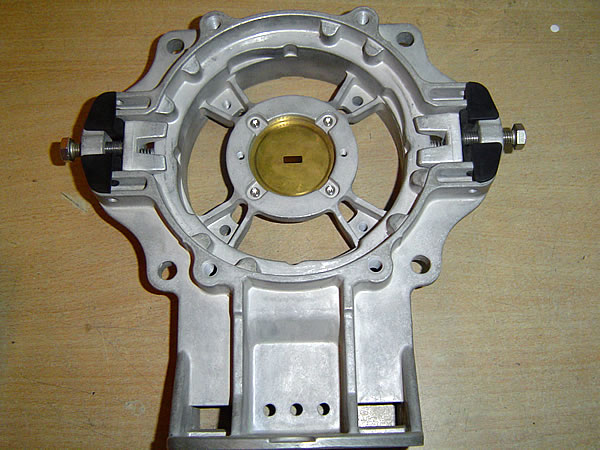

Our die casting service engineers are outstanding when it comes to using high-pressure die casting in producing intricate shapes with repeatability, durability and dependable quality. Also, brass die castings are recommended for rugged durability, electrical conductivity, neatness and beauty. Aluminium die castings, however, are preferred for performance, looks and low cost. With unmatched capabilities, we can produce the components you need keeping your requirements in mind. Be it for short and long runs, net or near-net results, thin or thick walls, excellent mechanical and electrical properties. Apart from this, cost-effective alternatives to other casting and pressure die casting processes also come under our umbrella. We use considerable pressure to inject molten metal into a steel mold or die cavity to form products at Start Prototyping. The molds or dies we use can produce complex shapes with exceptional accuracy and repeatability.

For products that are stronger, lighter, complex or intricately shapes, finished finely in desired textures, through top quality pressure die casting service, get in touch with us today!

What Is Pressure Die Casting?

Pressure die casting is the process of making high fidelity copies of your designs by injecting molten metal into custom made steel dies. It’s the most cost effective way to produce medium to high volumes of metal parts with excellent surface finish and dimensional accuracy.

Advantages Of Die Casting

- Castable metals include aluminum, zinc and magnesium

- Mold tools can make tens of thousands of parts economically

- Surface finish and accuracy are excellent

- Complex geometries can be achieved

- Especially suited for larger metal parts

Start Your Project Today

When you send us your 3D CAD files, our technicians will evaluate your requirements and advise the best combination of services to meet your expectations.

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials

50+

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials