Additive Manufacturing

Discover the principles and benefits of using additive manufacturing to create amazing products from 1 to 10,000 units.

Additive Manufacturing Service China

With more than 20 years of additive manufacturing experience, Start Prototyping offers a wide variety of rapid prototyping services. Whether you need an attractive presentation model, a durable piece for product performance testing or even a metal piece, our team of engineers can help you get exactly what you need – fast.

Additive Manufacturing Services Include:

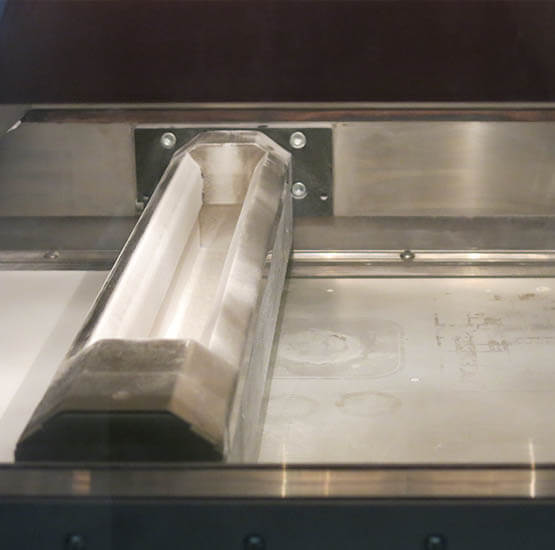

Metal 3D Printing also known as DMLS/DMLM is an additive manufacturing technology that provides high precision metal parts. The layer additive process is suitable for all industries requiring custom fast turnaround metal parts. Production injection molding tooling created offers injection molding companies extended possibilities for high performance manufacturing. This design freedom allows the integration of conformal cooling channels, which improve the quality and speed of injection molded parts.

3D Printing (3DP) is a rapid prototyping technology that provides high precision plastic 3D models. The layer additive process is suitable for proof of concept models and inexpensive prototypes of new products.

Stereolithography (SLA) produces accurate models from a wide range of UV curable resins, comparable to ABS, Polycarbonate and Polypropylene. The resulting prototypes are suitable for form, fit and function testing as well as urethane casting patterns.

Fused Deposition Modeling (FDM) is a rapid prototyping and additive manufacturing technology that can produce ABS, PC and ABS/PC parts without the need of expensive tooling. This is ideal for short run parts with quick turnaround times.

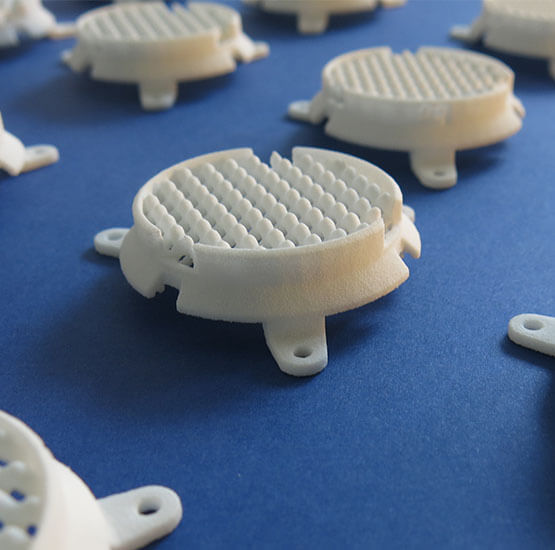

Selective Laser Sintering (SLS), provides accurate models from sintered nylon powder. They can be used for form, fit and function testing as well as limited run production. This process is ideal for complex parts as supports are not needed during the build process.

Our Works

What is Additive Manufacturing?

Additive manufacturing is a relatively new concept, made possible by vast improvements in resins and materials used in the processes. Until recently, a Stereolithography prototype would not have been suitable for use as a finished product – though fit and finish would have been correct, durability would have been lacking.

Fortunately, the resins used in additive manufacturing today allow for the creation of fully functional items that can be used immediately. This means additive manufacturing has become a viable method of creating finished goods. And because those resins and materials are always improving, Start Prototyping can create an ever-growing variety of items using additive manufacturing techniques.

The Benefits of using Additive Manufacturing

Additive Manufacturing is particularly effective specifically where more traditional manufacturing methods are inefficient. For companies and individuals, Additive Manufacturing is redefining the relationship between design and manufacturing, considering that an object can be produced if it can be imagined . While traditional manufacturing has constraints and limitations , Additive Manufacturing enables a freedom of shapes, forms and quantity. Additive Manufacturing allows :

- the production of functional parts printed at once

- the production can take place in batches

- the creation of high-performance mechanical equipment

- businesses to offer mass customization

The most common Additive Manufacturing processes

Additive Manufacturing always starts with a 3D model generated by a CAD software (Computer Aided Design). This file will serve as a blueprint for the machine, by setting perimeters and guides for the material as it lays down layer upon layer. The 3D printer uses the information of the 3D file to create very thin layers of material, often thinner than 150 microns. Once all the successive layers have been created, the Additive Manufacturing process is considered done. Depending on the technology itself, the form of the raw material can vary from solid filaments, powder, to liquid.

Why Start Prototyping additive manufacturing?

Start Prototyping’s two decades of experience in the additive manufacturing industry makes us the ideal partner. We specialize in creating market-ready items directly from 3D CAD models, allowing for:

Zero or near-zero tooling costs, which are usually rather high

Low production cost overhead

Vastly increased production speed

Vastly decreased time to market

What is a good part for additive manufacturing?

A typical item that Start Prototyping can create with additive manufacturing has these characteristics:

Small size

Low quantity

Previously made with low volume injection molding, epoxy or aluminum tooling

Limited product life span

Defined quantities needed

Geometry that cannot easily be made using traditional manufacturing methods

Start Your Project Today

When you send us your 3D CAD files, our technicians will evaluate your requirements and advise the best combination of services to meet your expectations.

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials

50+

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials