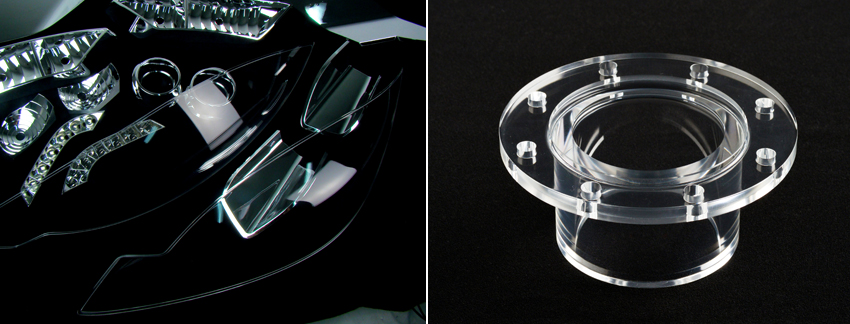

Optical Prototype Machining

Start Prototyping can provide a one-stop machining service for the automobile lighting prototype. Of course, we have a large number of cases to follow. Years of experience in automotive lighting prototype machining to ensure that we can provide you with the highest standard automotive lighting prototype machining services. We have many sets of machining plans, from design of automobile lighting, headlamp, taillight, fog lamp, to the test of the photometric development engineering. It is a relaxing and pleasant thing for us.

Optical Prototype Machining China

In industrial applications, many machines have this strict requirement for clear optical components, such as car lighting, automobile industry (signal lighting equipment, dashboard, etc.), medical industry (blood storage container, etc.), industrial applications (DVDs, light scatters), and key electronic products (especially transparent).

The processing of high quality optical parts has a higher demand for manufacturers, operators, machining equipment, and knowledge reserves. Fortunately, Start Prototyping is a good one of the prototype manufacturers with clear optical components, we pay special attention to the processing the details of optical parts, without any marks or scratches.

PMMA Prototype Machining

PMMA prototype machining is one of the main businesses of Start Prototyping. We know well about clear optical prototypes, without any traces or scratches after processing. In the process of PMMA machining, our flexible and diverse work methods and work plans enable us to fully support PMMA prototype projects. For example, Peter, a car prototype designer from canda, said to us that Start Prototyping is a great prototype manufacturer, full of service to me, and the manufacture of the car ligths has realized my dream for many years.

Acrylic Polishing

Acrylic resin is a good light permeable material, which has the characteristics of crushing, weathering, UV stability, stable size, good heat insulation performance and good thermal stability. CNC acrylic polishing process needs to remove excess materials and obtain good finish before polishing. Start Prototyping used the skilled craftsmen to use polished ointment to polish the archetypal surfaces according to the requirements of different polishing grades, and to leave high quality polishing effects, which can be applied to windows, signs and lighting devices, and supplies with almost undistorted clarity.

Polycarbonate Prototype Polishing

Polycarbonate is one of the most common transparent plastics, and its definition is only next to acrylic acid. The processing of polycarbonate is usually done by vapor polishing. vapor polishing is an ideal method for polycarbonate polishing. It can improve the internal and external surface polishing of polypropionate prototype. It can remove slight scratches and irregular shape particles, and use chemical reaction to corrode the surface of plastic to achieve smooth. In the process of vapor polishing, rich experience is one of the keys. Fortunately, Start Prototyping fully grasps this technology.

Usually, Methylene chloride vapor is used to polish polycarbonate. Methylene chloride generates steam when heated to boiling point and exposes the polycarbonate prototype in steam less than three seconds in a dust-free room. In the process of polishing, the polycarbonate prototype must be dry, and special equipment is needed to achieve the desired results. Only the experienced mechanic can operate, otherwise the situation will become very bad, and the appearance will appear white foggy texture.

Start Your Project Today

When you send us your 3D CAD files, our technicians will evaluate your requirements and advise the best combination of services to meet your expectations.

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials

50+

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials