Medical Parts Machining

Start Prototyping has rich experience in medical prototyping. We are proud and honored to provide comprehensive rapid prototype and manufacturing solutions for some of the world’s leading medical & healthcare companies, such as Beckman Coulter, GE Healthcare, Philips Healthcare and Becton Dickinson. We consistently produce high fidelity physical prototypes that will pass the most rigorous verification and testing procedures.

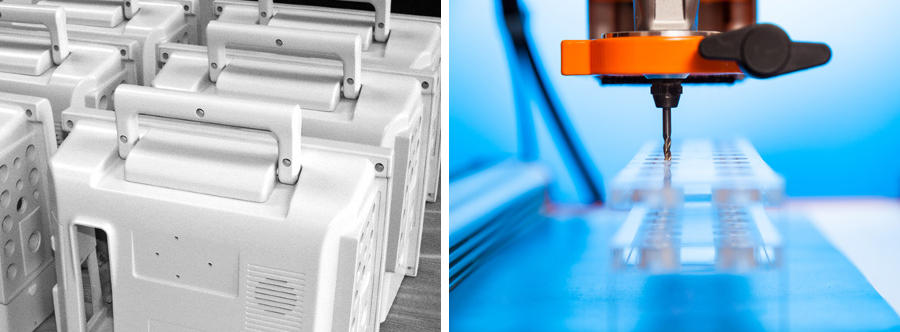

Medical Parts Machining China

The medical industry needs high quality, dependable and safe parts and products so they can deliver healthier and happier lives to all. At Start Prototyping we have been working with medical device manufacturers large and small, old and new to deliver high-quality precision parts and prototypes. Our rapid tooling and injection molding services also offer the perfect solution for low/mid volume production and medical grade materials.

Our massive range of customer-focused services allow you to iterate rapidly and offer customised solutions to your clients fast.

We understand the unique demand and challenges that our medical clients face with their designs and work with them to ensure they are met and exceeded.

Start Prototyping offers reliable rapid prototyping and rapid manufacturing solutions for the medical device industry. From hand-held appliances to anatomical models and large-scale treatment units, we can be relied upon to create genuine products. Our delivery is always timely: regardless of the quantity of medical end-products in our production systems, customers can bring their products to market on time. Besides enjoying quality products that operate with precision, our customers also enjoy our affordable rates.

Start Prototyping provides medical prototype machining and medical device design services. Our CNC machining centers include 4 – and 5 – axis milling and 3 – axis turning, which can provide precision prototype machining. We are “one-stop service” prototype manufacturer that meets the needs of all your medical device machining. Our team can use all kinds of materials, including aluminum, steel, plastics, rubber, ceramics, titanium, refractory metals and superalloys, but the most commonly used materials include PEEK, titanium, 316L, or medical grade stainless steel, cobalt and chromium. CNC milling and turning are the key aspects of medical device manufacturing.

In the process of medical prototype machining, CNC prototype machining with low costs and shortens delivery time is easy to accept design changes and secondary operations without requiring cost consumption, and is competent for rapid switching from manufacturing one prototype to another. secondary operations, such as drilling and tapping, can be completed in the machining center. Of course, the beauty and function of the medical prototype can be kept in accordance with the designed drawings, polishing, plating or anodic oxidation can be used to process threads and tapping in multiple angles of the medical prototype. Medical prototype machining can withstand higher temperature and higher strength material selection. The advantage of multi axis machining equipment is to achieve more complex geometries, small precision grooves, and threaded parts that maintain strict tolerances and extreme conformance.

Prototype Machining Company

Customers need a one-stop prototype machining company, with ability to carry out Secondary operations, such as laser engraving, electroplating, anodizing, coating and so on. It is simpler, easier and more efficient to have only one company to undertake all the work than to deal with a number of prototype manufacturing companies.

Prototype machining companies that provide secondary operations services and one-stop services are more competitive when they develop partnerships with medical device manufacturers.In addition to sophisticated machining services, AN-PROTOYPE can also help medical prototype designer optimization, eliminate unnecessary operations, the most limited machining steps and materials, thus saving precious time and money for your project.

From prototyping to mass products, Start Prototyping is the primary resource for your medical device machining. The excellent mechanists of Start Prototyping succeeded in helping us to get a reputation, providing quality services and high quality parts, and winning the reputation of the medical device experts; from the prototype to mass production orders. Through our rapid tooling, Japanese machine tools, high speed multi axis milling centers, precision CNC machining, the highest quality products are applied to the medical industry, it is a great honor to establish a partnership with any company.

Start Your Project Today

When you send us your 3D CAD files, our technicians will evaluate your requirements and advise the best combination of services to meet your expectations.

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials

50+

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials