CNC or 3D printing

As a service company for rapid prototyping in the automotive, medical and aerospace, electronic and other industries, Start Prototyping’s field of work is to select the right machining technology for the specific application, delivering results and to cost 30%-50% less than Europe and America.

CNC or 3D printing China

Start Prototyping as a prototype manufacturer in China,workshop is divided into two areas, one for plastic and one for metal. Start Prototyping plant covers an area of 20,000 square feet and has more than 250 full-time staff. Start Prototyping prototyping services include 3D printing (especially SLA and SLS), CNC machining,vacuum casting,rapid tooling and plastic injection molding.

As a service organization for rapid prototyping in the automotive, medical and aerospace,electronic and other industries, Start Prototyping field of work is to select the right machining technology for the specific application ,delivering results and to cost 30%-50% less than Europe and America.

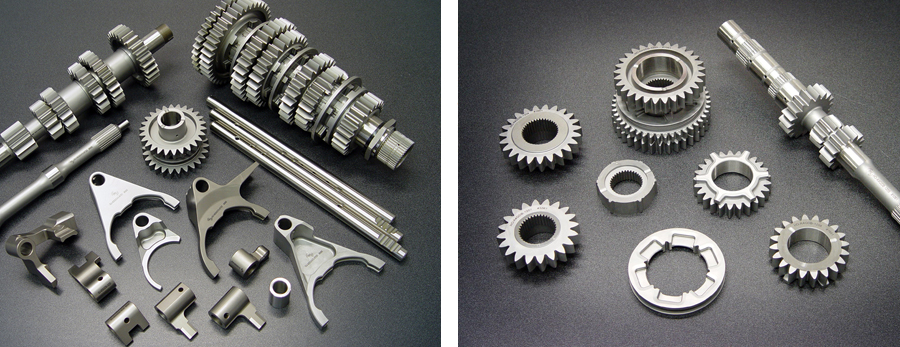

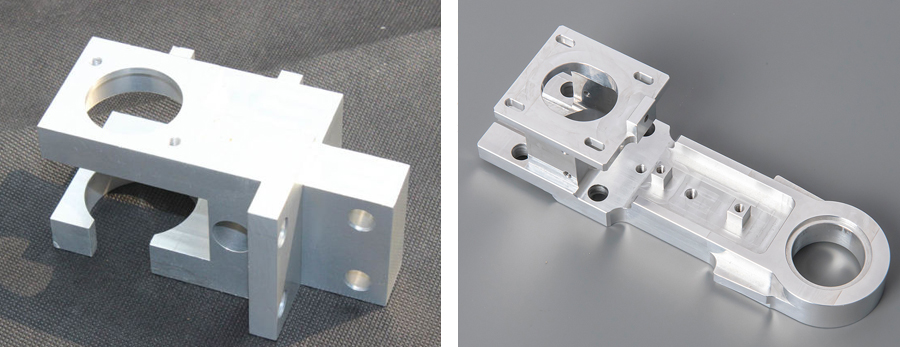

In the case of CNC machining, solid material blocks can be used. One of the main advantages of this process is the availability of materials, almost all materials can be machined by CNC. For this reason and its use in industry since the 1940s, CNC machining is still the most commonly used prototyping tool so far.

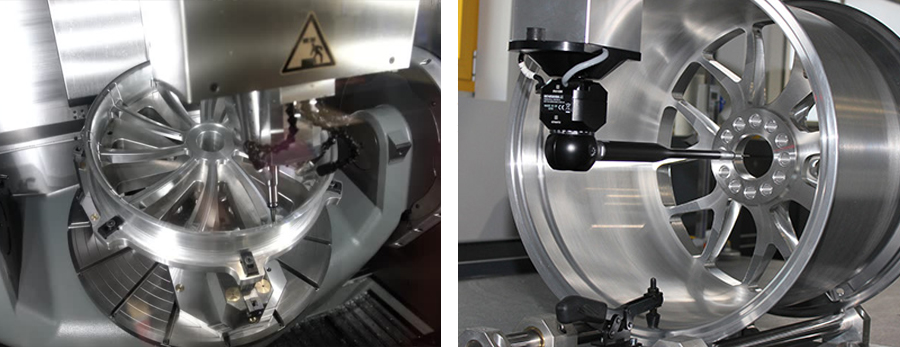

Start Prototyping specializes in CNC plastic machining and cnc aluminum machining. During the CNC processing, the tool head rotates to gradually remove material from the solid block. Thus, the molecular stability of the solid block remains constant and the resulting part has the original tensile strength.

Precision tool paths in CNC machining create excellent smooth surfaces, parts can be polished and finished on the same machine. This method is very suitable for manufacturing the main model of casting products and pressure-resistant products. Aluminum products are lightweight and corrosion resistant and are widely used in aircraft and automotive manufacturing. As of 2017, Start Prototyping already has a five-axis machining center to improve the efficiency and precision of CNC parts.

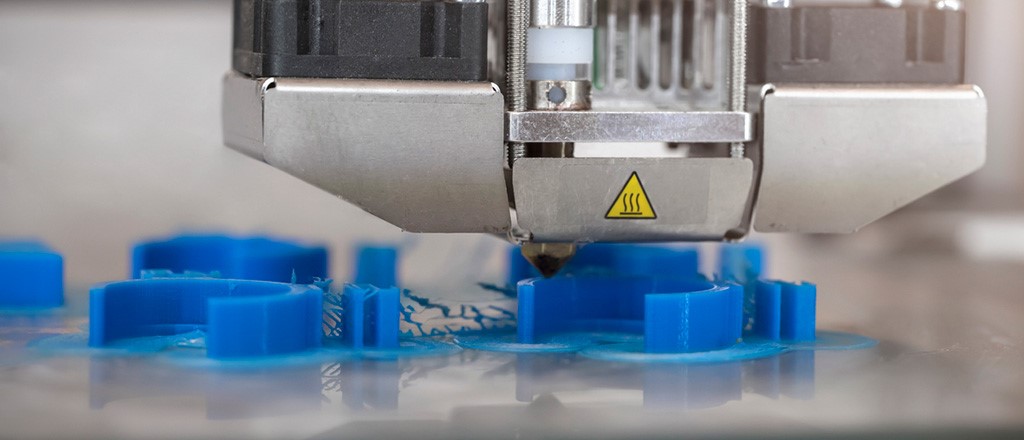

3D printing

The 3D printing service of Start Prototyping is mainly driven by laser, which provides high efficiency and precision. Start Prototyping stereolithography (SLA) is a UV curing process, while selective laser sintering (SLS) uses carbon dioxide laser.

The main SLA material used by Start Prototyping is a photosensitive polymer similar to ABS, which is suitable for the dewaxing method favored by jewelry manufacturing and dental industry. SLS uses powdered nylon material, which acts as a support material throughout the 3D printing process, reducing the post-processing time. Parts made with SLS also benefit from the potential of nesting, which means that more designs can be printed in the same version in 3D printing.

Both 3D printing processes can achieve rapid turnaround, usually only 2-5 days, which means that the product can be tested and modified before reaching the final prototype. With minimal material waste and operating costs, the price of 3D printing is very competitive.

Choose the right processing technology

The question is – which technology should you choose? As a spokesperson for Start Prototyping said: “The cost comparison between 3D printing and CNC machining is difficult to get a standard answer”, but the technology should be chosen according to the application.

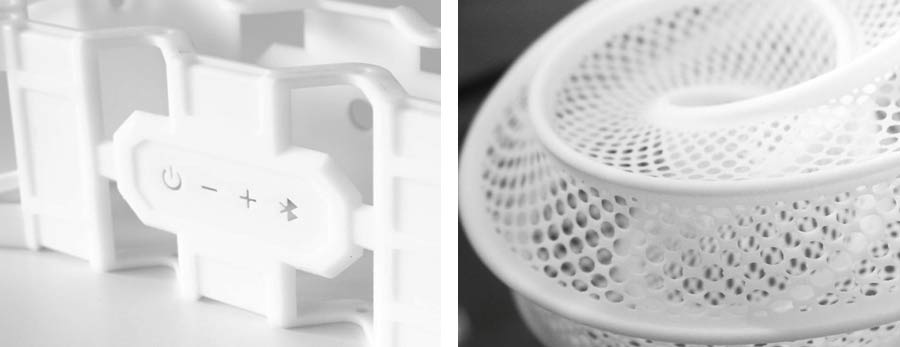

SLS and SLA

3D printing are very useful for fast response solutions. Using digital operating tools such as the slicer software, the process does not require the same professional training as CNC machining. With very little labor, the manufacturing cost of 3D printing is priced based on the weight of the material. 3D printing is advantageous for small size and lightweight components due to the higher cost of larger components. Start Prototyping’s 3D printing service has a simple structure and low requirements for surface quality and precision parts. This technology is suitable for prototypes of small medical devices, industrial tools and power tool housings.

On the other hand, Start Prototyping’s CNC machined parts can be used to make functional prototypes for engineering evaluation and testing. Compared to the SLA and SLS services offered, CNC machining requires specially trained engineers to pre-program the machining parameters and toolpaths and then process them according to the program. Therefore, manufacturing costs are based on extra labor. The advantage of CNC is the machining of parts with special requirements such as dimensional tolerances and surface quality.

In some cases, it is beneficial to achieve the ultimate goal by combining the process of increasing and reducing the material. For example, SLA and SLS can be used as preliminary processing before CNC processing.

The case of Start Prototyping include rapid prototyping in the automotive industry and development of medical devices.

Start Prototyping’s rapid prototyping cases include the automotive industry, medical devices and other industries. 3D printing is increasingly used throughout the medical industry. In the medical industry, 3D printing can be used to make hand-held appliances, conceptual models and small batches of new equipment such as diagnostic equipment, surgical instruments, electronic equipment and ultrasound systems. These devices are valuable for surgical planning, simulation, and mapping of dental correction procedures.

For the automotive sector, Start Prototyping applies a large number of CNC prototypes and rapid machining methods to the production of automotive components. These services are very useful for automotive manufacturers to run functional tests, and of course custom parts can be processed. Start Prototyping’s automotive rapid prototyping provides a complete range of services, through conceptual design reviews and mechanical component engineering test reports, to guide customers in demonstrating external/internal prototypes of automotive parts.

For all processes, Start Prototyping engineers can provide 3D data and design verification before producing parts.

Start Prototyping Guide

In terms of solution, CNC machining accuracy is usually better than 3D printing, and the accuracy is between 0.02mm and 0.05mm-0.10mm depending on the part structure and size. The turnaround time for 3D printing is usually 2-5 days faster than CNC machining, while CNC machining takes 3-8 days. A typical SLA/SLS operation can create 1-10 parts, while CNC machining ranges from 1-50 parts.

The competitive price of Start Prototyping is usually 30%-50% lower than the price in the US or Europe because of lower labor costs. In addition, projects can be launched quickly compared to other rapid prototyping companies. “

Start Your Project Today

When you send us your 3D CAD files, our technicians will evaluate your requirements and advise the best combination of services to meet your expectations.

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials

50+

Parts 3D Printed

10,000,000+

3D printing technologies

10+

Professional materials